设备技术参数:

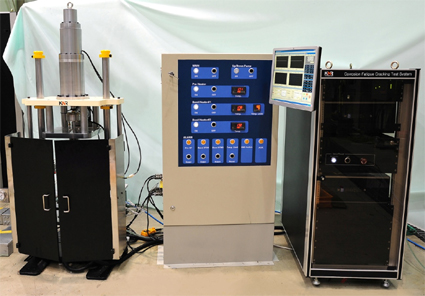

腐蚀疲劳裂痕测试系统是一个检测工程材料在高温高压环境下的机械性能的设备,尤其是核电站用材料,能够再现核电站一回路工作环境。该设备能够实现的实验过程包括:拉伸测试、低周疲劳测、蠕变测试、应力腐蚀测试和慢拉伸应变测试等,且所有的测试均可在高温高压下开展。该设备共分为三个部分:控制系统、伺服系统和工作系统,其中控制系统是设备的命令控制中心,配备两台计算机,用来输入实验参数、监测设备运行情况和记录实验数据;伺服系统根据控制系统输入的参数,通过继电器发生相应的操作,同时监测系统中的工作传感器;工作系统是根据控制系统和伺服系统给予的信号,做出相应的动作,如升降温度、施加力等。设备的主要参数如下表所示:

项目 | Item | 参数(Parameter) |

型号 | Model No | 302DE SC1 |

最大加载力 | Maximum test load | 20KN |

行程速度 | Crosshead speed | 0.0001mm/min to 10 mm/min |

测试频率 | Testing frequency range | 0.001Hz - 1Hz |

最大行程 | Maximum displacement | 50 mm |

测试环境 | Test environment | 350℃, 16MPa Max. |

Corrosion Fatigue Cracking Test System

This system is designed for evaluating mechanical properties under high temperature and high pressure environment. User can carry out various mechanical tests such as tensile test, Low Cycle Fatigue Test, SCC test, Creep test, Slow Strain Rate Test, etc. Inner displacement sensor is adapted to prevent friction error, also the proven software help user to define test procedure and to monitor test results easily.

The picture shows the main layout of the system, working parameters as the table presentation.

万能摩擦磨损试验机

万能摩擦磨损试验机是用于测试材料的表面摩擦磨损性能的设备,通过干摩擦的方式测试材料的抗摩擦性能。设备已经通过ISO质量体系认证。该机可以滑动、滚动或滑滚复合动力的摩擦形式,在一定的接触压力、于极低速条件下,评定润滑剂、金属、塑料、涂层、橡胶、陶瓷等材料的摩擦磨损性能。配有销-盘、四球、球-三片、销-三柱、止推圈,球盘、模拟凹轮、齿轮等多种形式的摩擦副,可以做多种配对形式的摩擦磨损试验。配置有专用测试软件,能对测试参数进行采集、处理、显示并打印。设备的相关参数如下表所示:

项目 | Item | 参数(Parameter) |

最大加载力 | Maximum test load | 1000N |

加载力相对误差 | Test load relative error | ±1% |

最大摩擦力矩 | Maximum friction torque | 2.5Nm |

主轴转速 | Speed of main shaft | 0.05~2000r/min |

工作温度 | Working temperature | 25~260℃ |

Multifunctional friction and wear tester

Multifunctional friction and wear tester is used to test the material surface friction and wear performance, it through the dry friction test way to test the material’s friction and wear properties. The equipment has been through the ISO quality system authentication. This machine can carry out slide, rolling or sliding rolling composite dynamic friction forms, it can evaluate lubricant, metals, plastics, coating, rubber, ceramic materials such as friction and wear performance on certain contact pressure or very low speed conditions. The system equipped with pin - disk, four ball, the ball - three pieces, pin - three column, thrust ring, simulation concave wheel, the gear and so on, it can do many kinds of matching form of friction and wear test. In addition, it has special test software, to test parameters acquisition, processing, display and print.